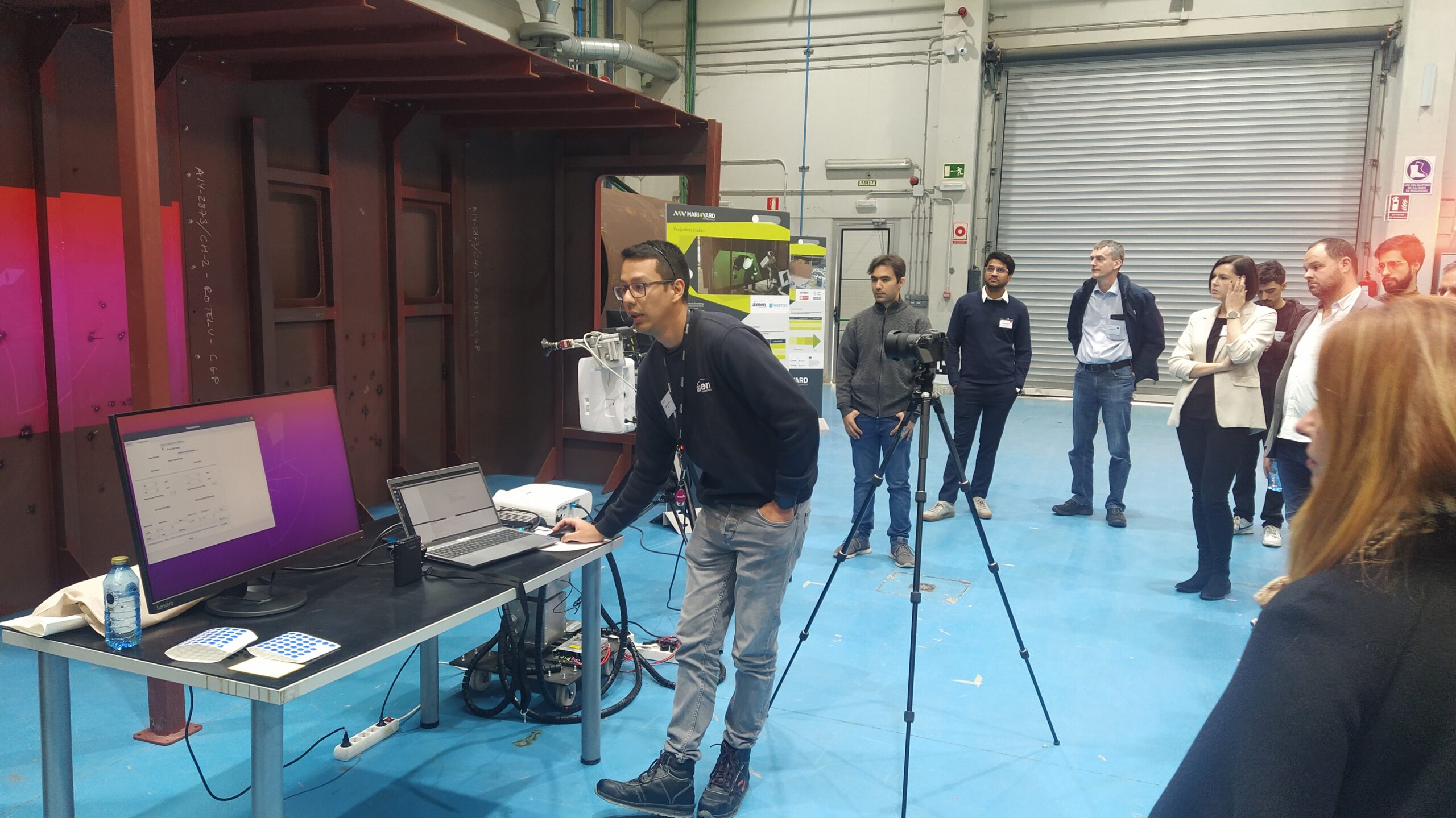

Mari4_YARD hosted its 4th Workshop in O Porrino, Pontevedra, Spain. The event took place on November 14th at AIMEN, Centro tecnologico, coordinator of the project.

What is Mari4_YARD? Mari4_YARD is a collaborative effort involving 18 partners from 9 European countries, including Spain, Germany, Croatia, Italy, Netherlands, Greece, Belgium, Portugal, and Poland. The project’s mission is to develop user-centric solutions for flexible and modular manufacturing in small and medium-sized shipyards.

Key Technologies Mari4_YARD is focused on developing innovative technologies to enhance shipbuilding efficiency and competitiveness:

- Digital Solutions for 3D Modeling: These solutions will streamline the retrofitting and repairing of vessels, reducing rework and changes by up to 60%.

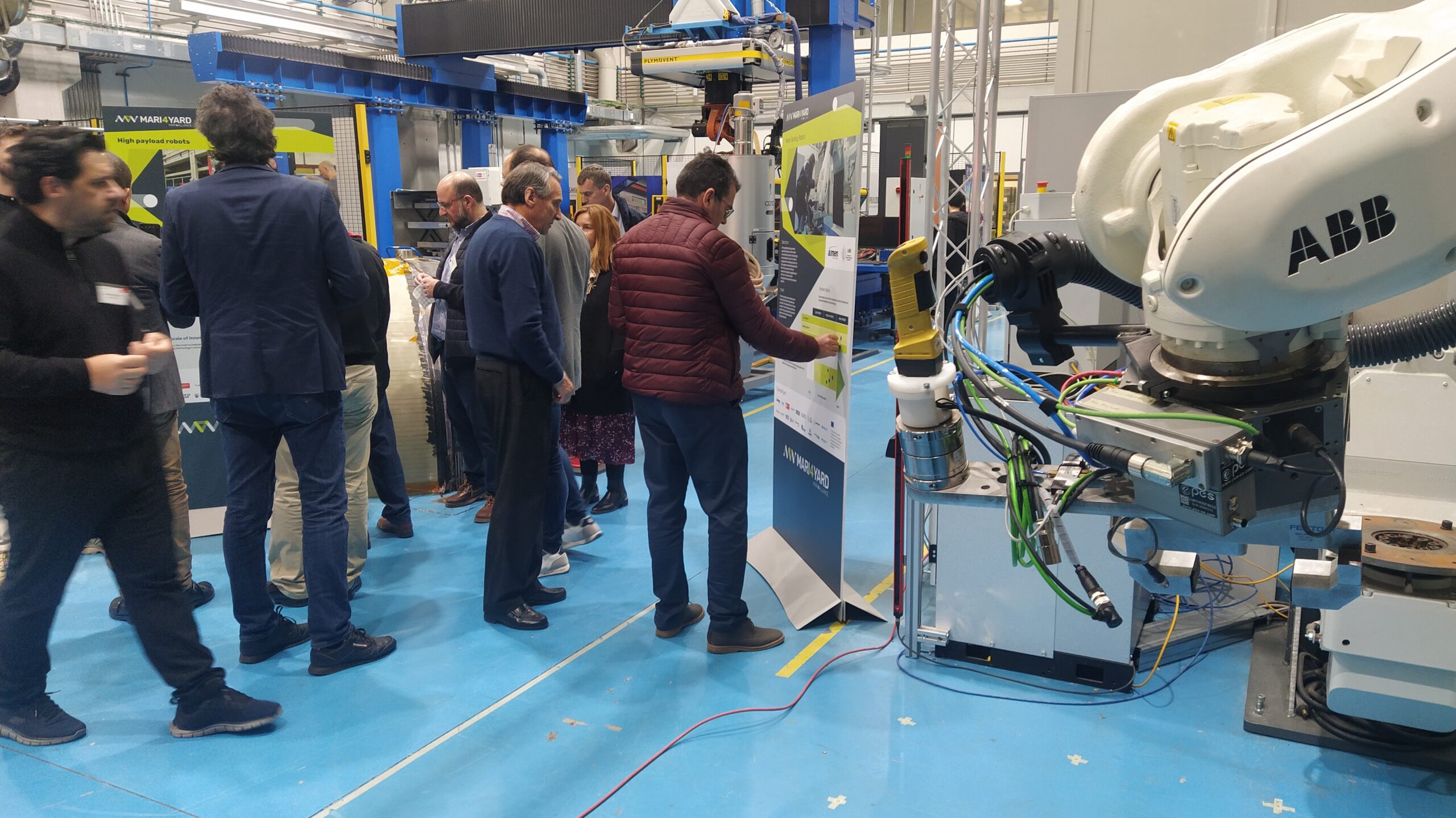

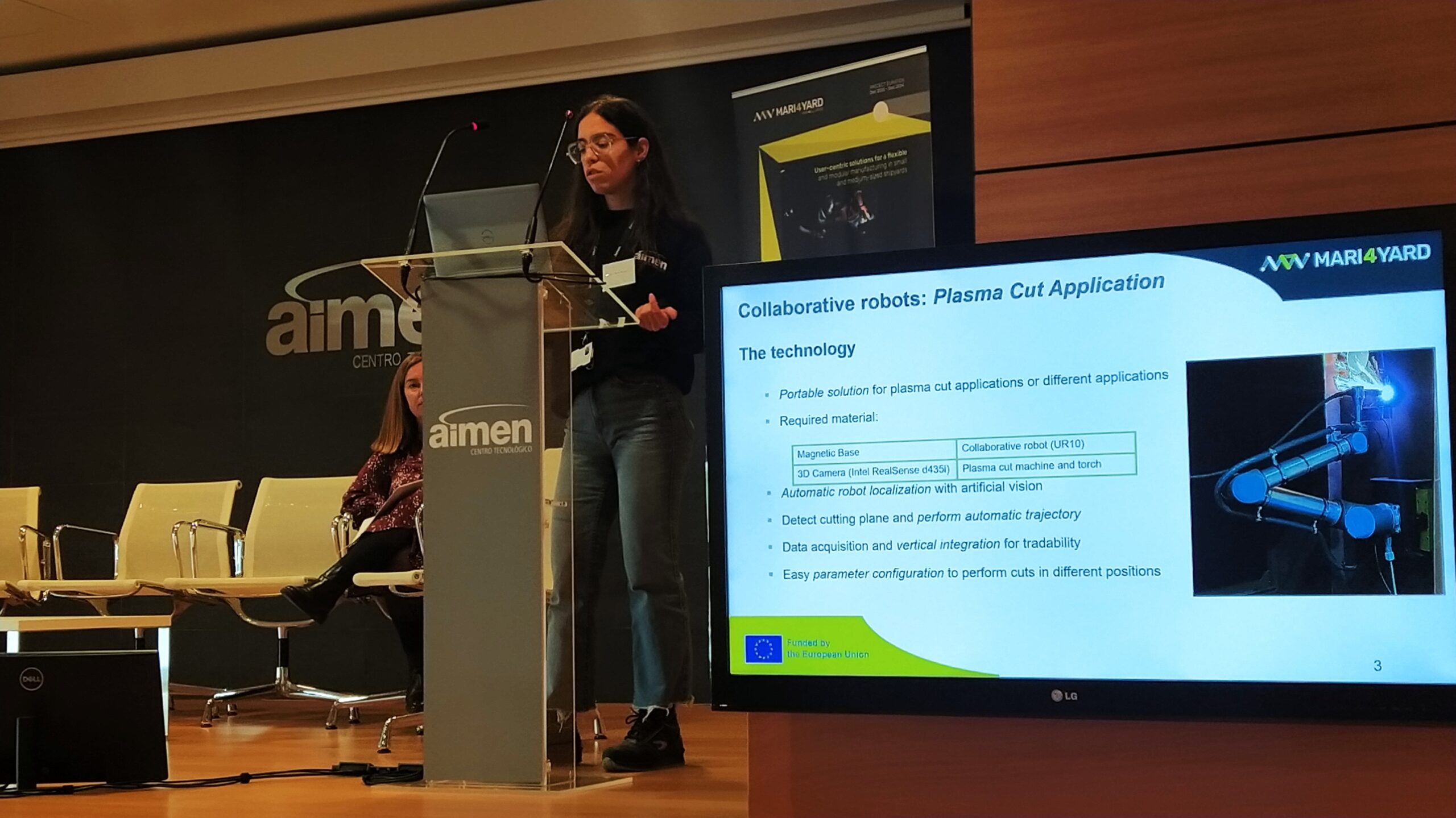

- Safe Robot-Based Solutions: Collaborative robots will be integrated into the shipyard environment to improve efficiency and reduce process time.

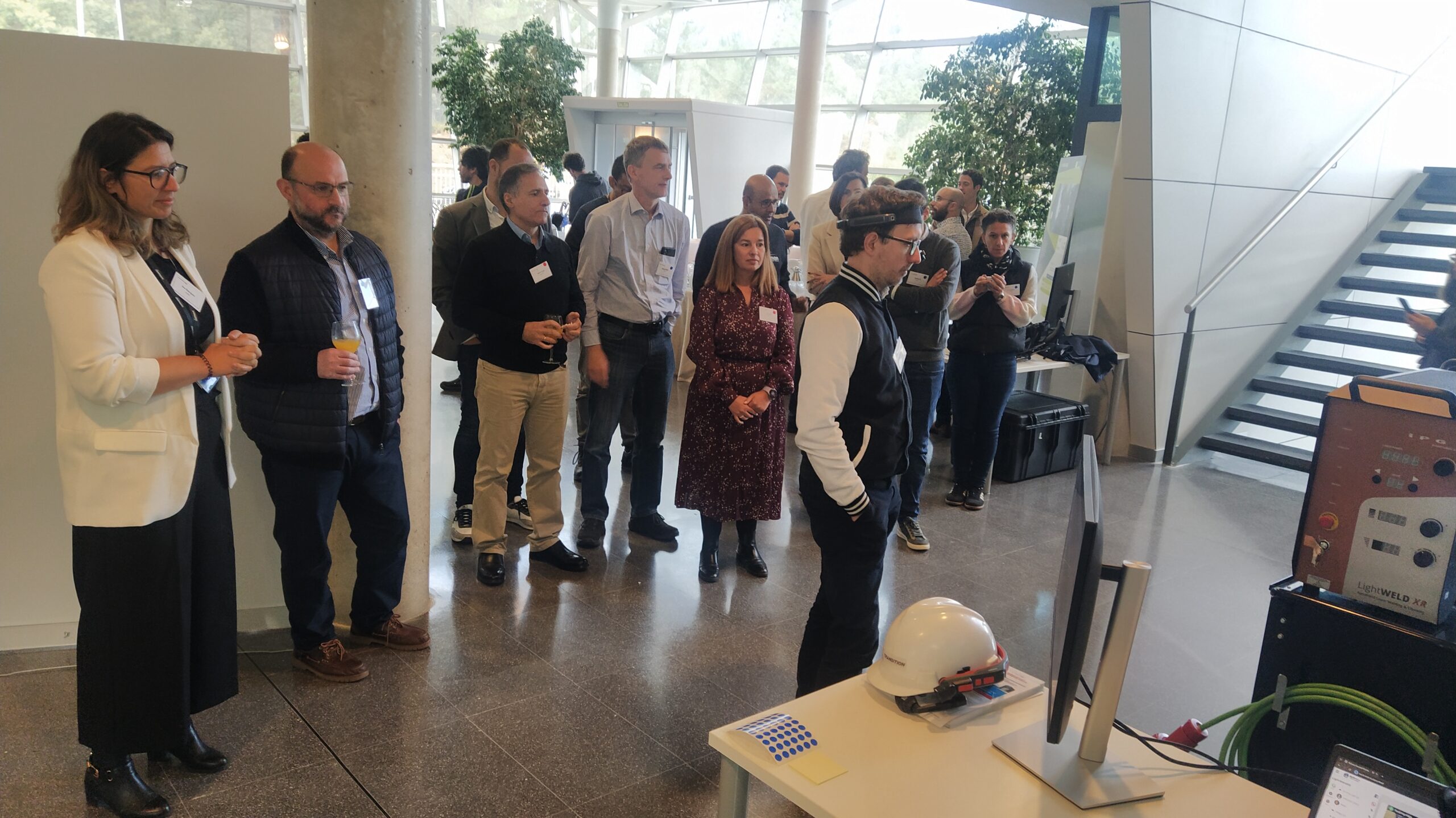

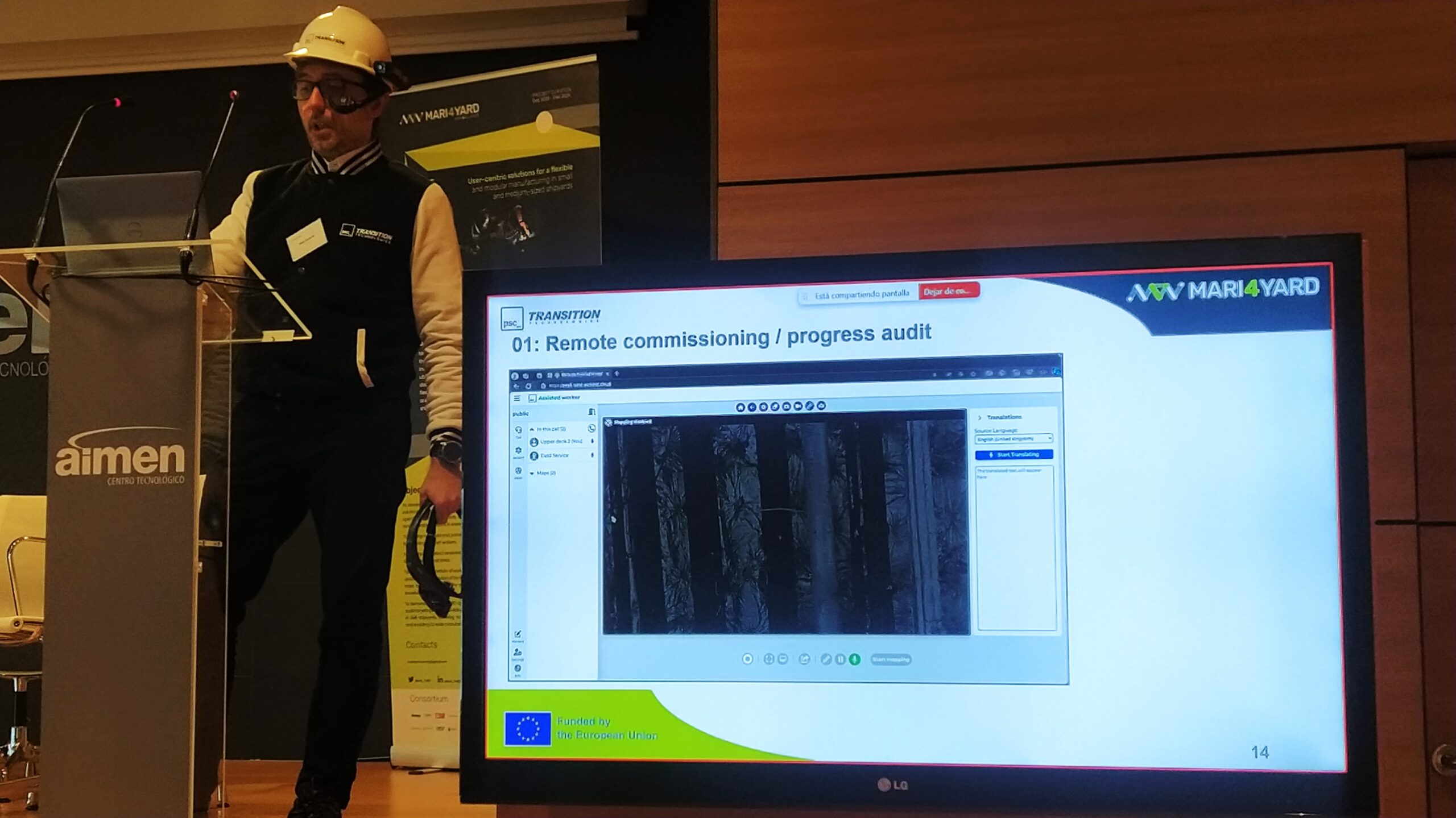

- AR/MR Tools: Augmented and mixed reality tools will assist workers in positioning equipment and subassemblies with greater precision.

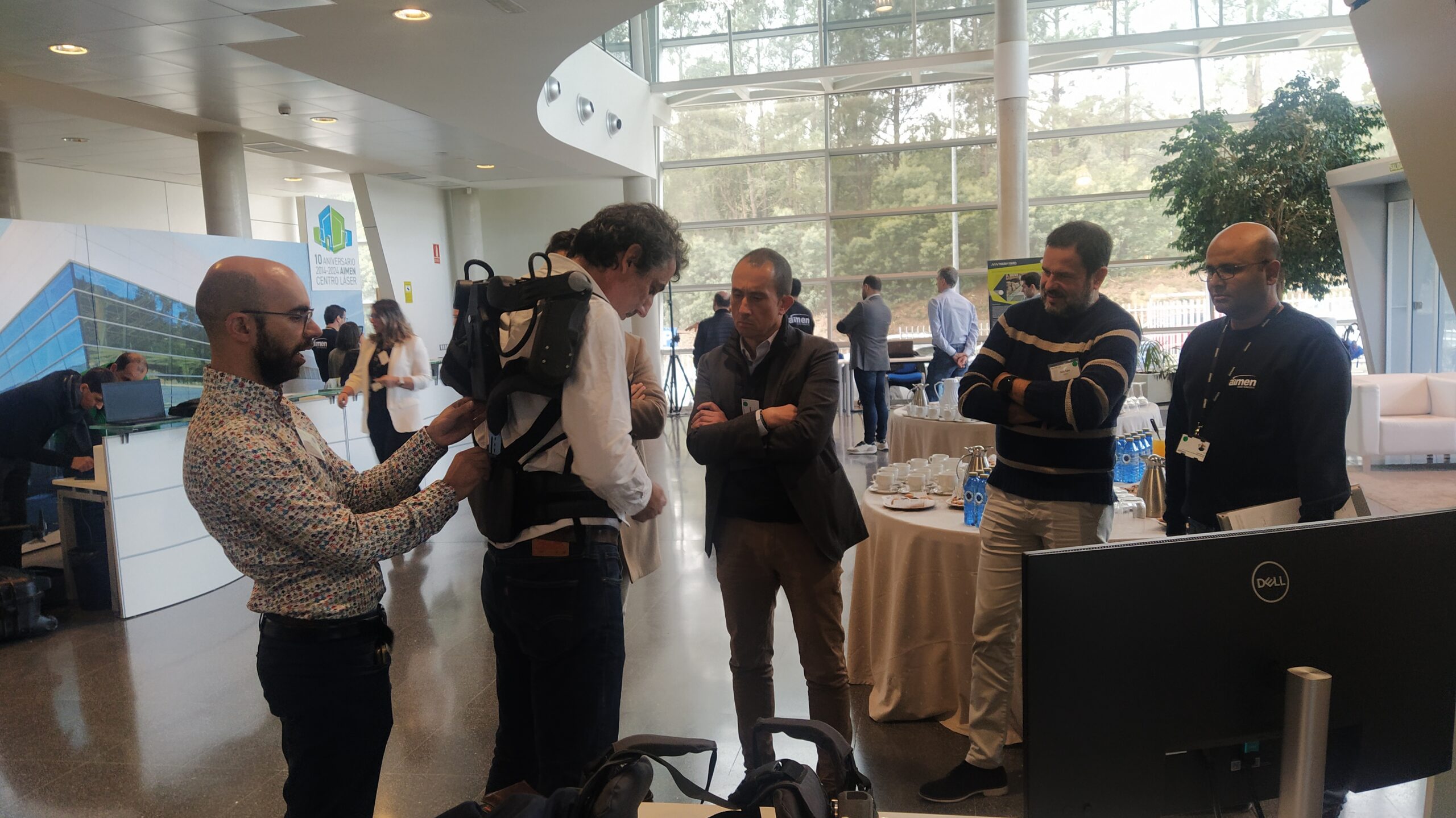

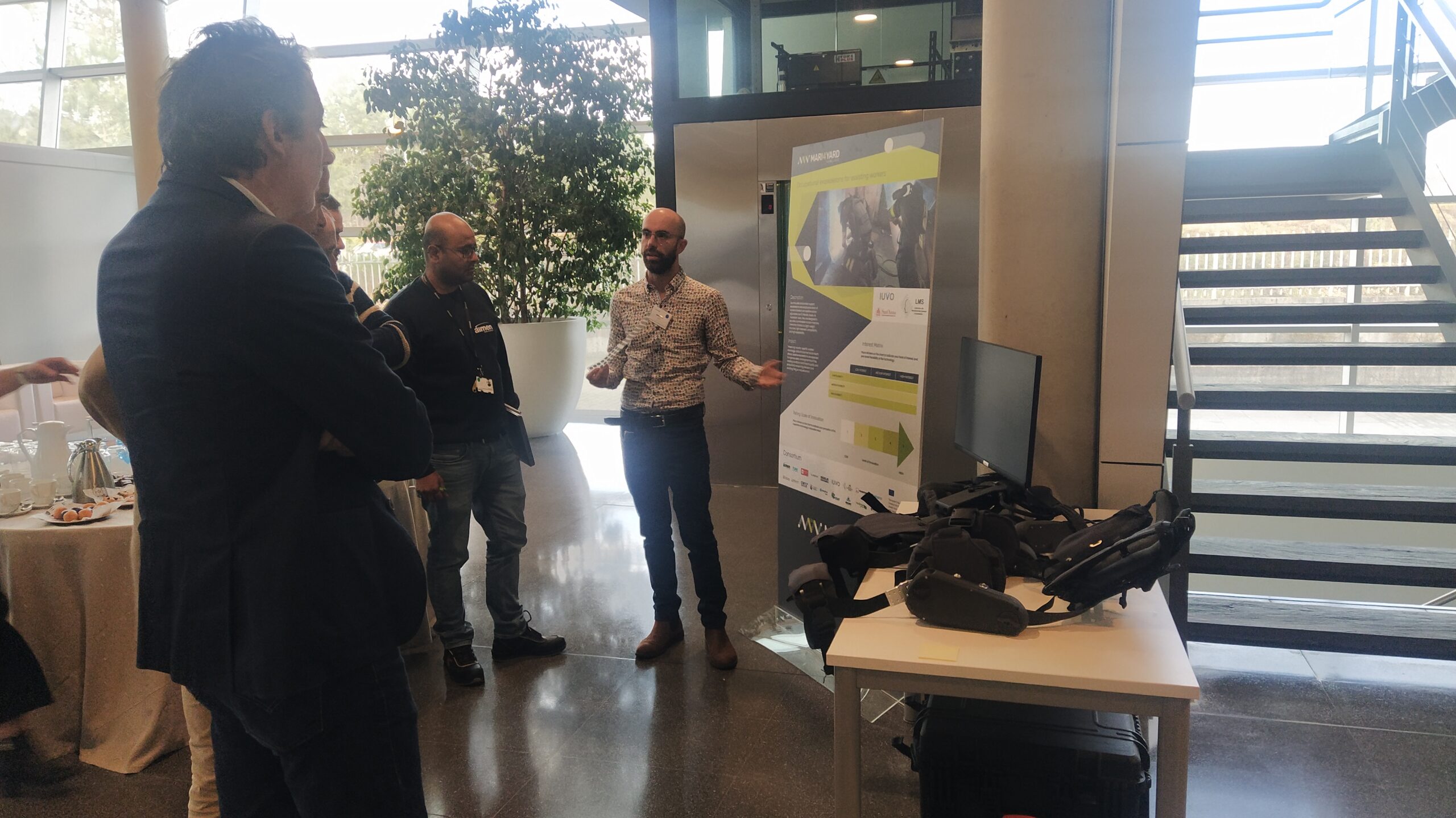

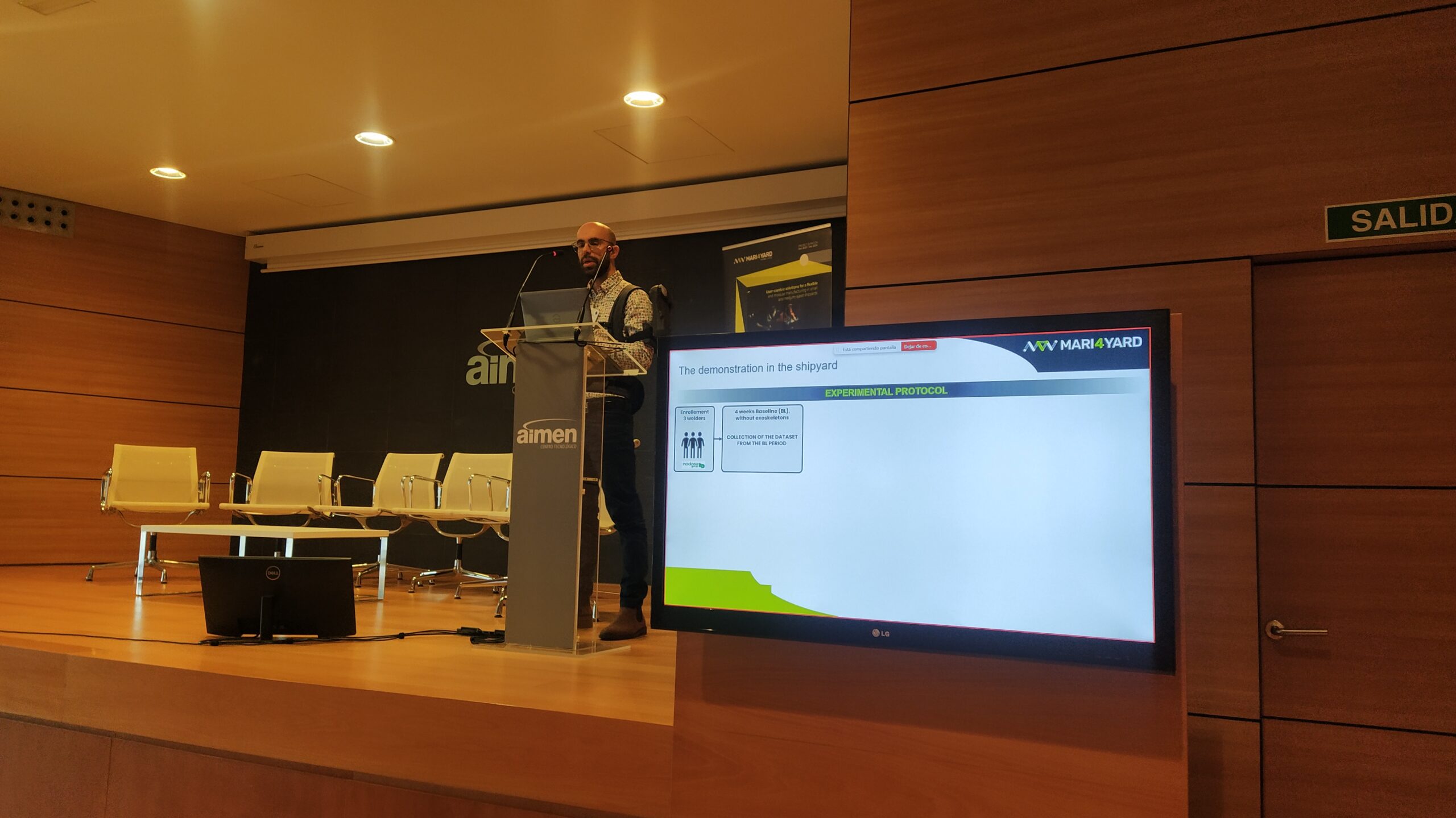

- AI-Enhanced Exoskeletons: Exoskeletons powered by AI will reduce worker fatigue and improve task quality and precision.

Why Mari4_YARD? The project aims to strengthen the competitiveness of European small and medium-sized shipyards, creating new jobs and fostering economic growth. By focusing on user-centric solutions, Mari4_YARD is poised to revolutionize the shipbuilding industry.

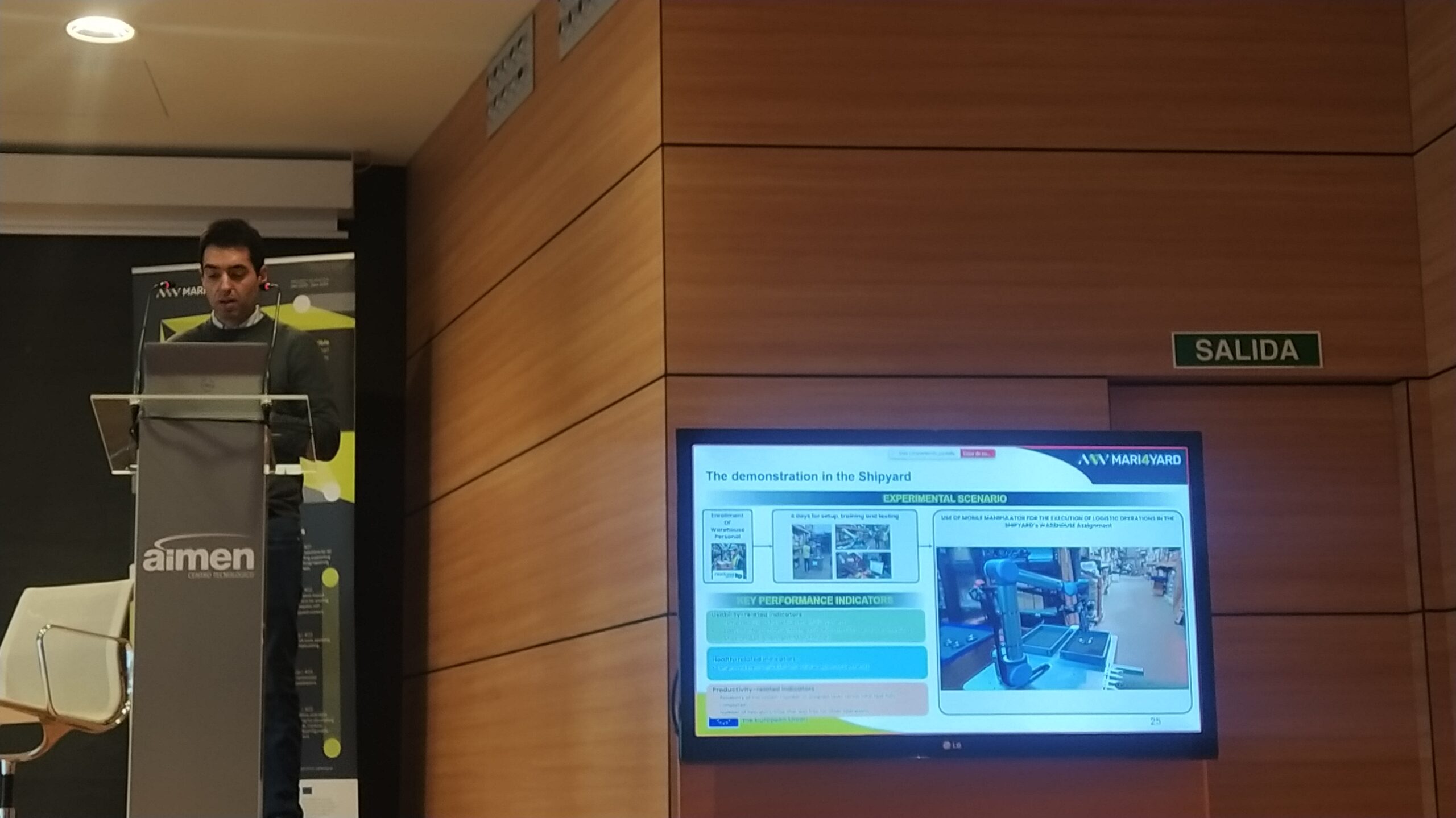

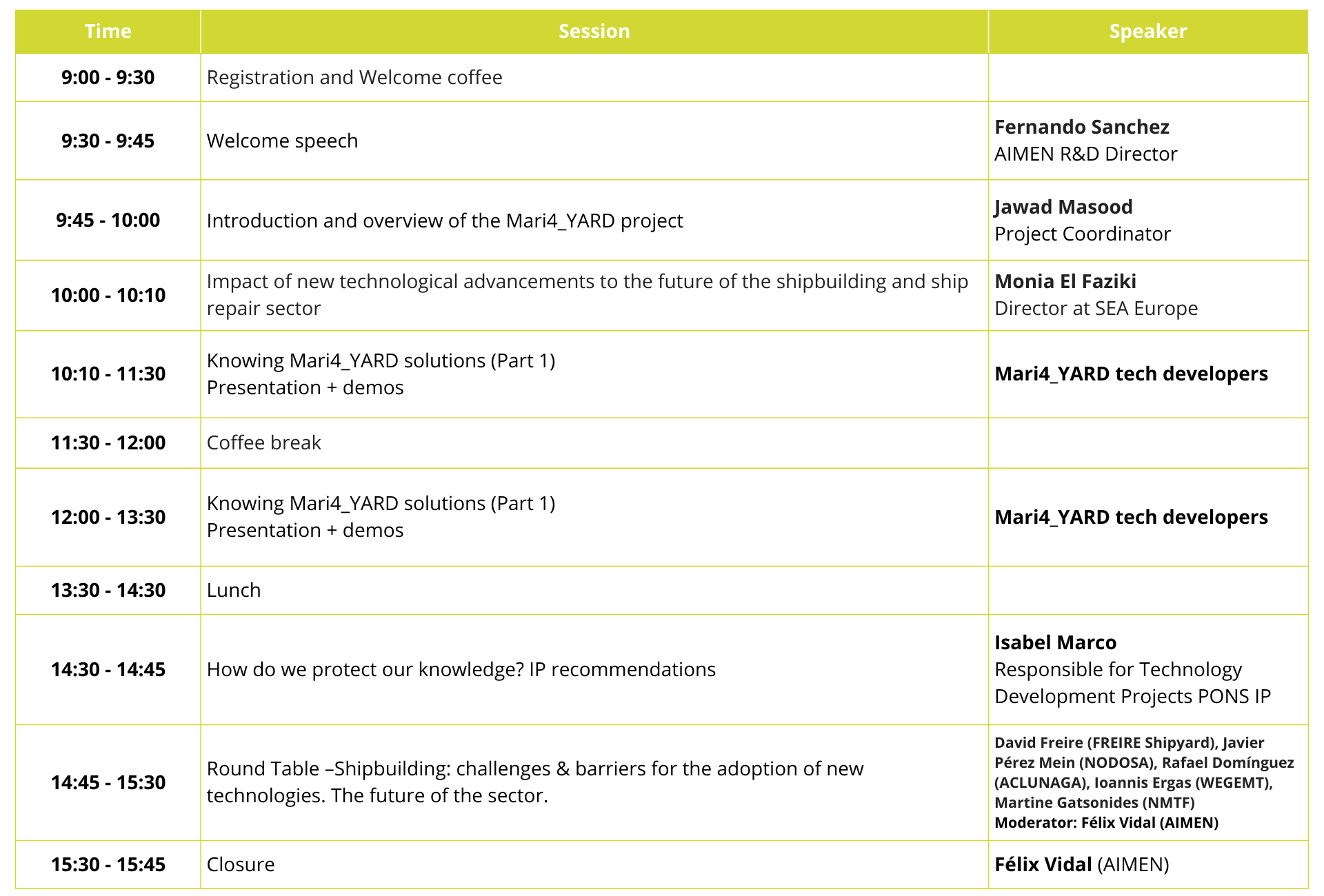

THE AGENDA

The afternoon round table at the 4th workshop of Mari4_YARD focused on the challenges and opportunities in maritime technology.

Our panelists represented the main categories of stakehlders relevant to Mari4_YARD:

from shipyards: David Freire from Freire Shipyard – C.N.P.FREIRE, S.A; Javier Pérez Mein from Nodosa Group;

Maritime associations: Rafael Dominguez Lago from ASOCIACION CLUSTER NAVAL GALLEGO; and Martine Gatsonides from NMT | Netherlands Maritime Technology;

Academic associations in Maritime: Ioannis Ergas from the European Association of universities in Marine Technology and Related Sciences (WEGEMT)

Highlights

Shipyard Challenges:

🔹 Real-world Testing. There’s a need to test new technologies in real-world shipyard conditions to assess their practical usability.

🔹Space and Cost Constraints. Implementing large-scale robotic systems requires significant space and investment.

🔹Production Disruption. Integrating new technologies into existing production processes can be disruptive and requires careful planning.

Workforce and Skills Gap:

🔹Attracting Young Talent. The maritime sector struggles to attract young talent compared to industries like automotive.

🔹Bridging the Academia-Industry Gap. Improved communication and collaboration between academia and industry can help address skills gaps and foster innovation.

Recommendations:

🔹Investment in Planning. Shipyards should invest in planning to prepare for technological advancements and upskill their workforce.

🔹Tailored Technology Adoption. New technologies should be tailored to specific shipyard needs and capabilities.

🔹Engaging End-Users. Involving end-users in the technology adoption process can increase acceptance and success.

🔹Strategic Consulting. A strategic consultant can bridge the gap between technology developers and end-users, identifying problems and recommending solutions.

🔹Leveraging Didactic Factories. Mari4_YARD’s didactic factories can help change end-user perceptions and drive adoption of new technologies.

By addressing these challenges and implementing the recommended strategies, the European shipyards can embrace technological advancements and ensure its future competitiveness.

Stay Updated Follow Mari4_YARD on LinkedIn and X for the latest news and updates.

Download the workshop presentations:

- Introduction – Project results overview

- Application for Onsite Support and Supervision (TUHH)

- Occupational exoskeletons for assisting workers (IUVO)

- AR/MR application for workers guidance (TTPSC)

- Mobile Manipulator for Intralogistics (INESC TEC)

- High-payload robots in shared space with humanss (LMS, GHIZELIS)

- Collaborative robots: plasma cut application (AIMEN)

- High precision projection system (AIMEN)

- Projection of cutting information for improving productivity, precision and reliability (INESC TEC)